Tunneling

NATM (New Austrian Tunneling Method)

New Austrian Tunneling Method (NATM), also called sequential excavation method, was developed from conventional excavation and excavates tunnel by drilling and blasting or roadheader. In this method various types of auxiliary tunnel supporting have been developed suitable to the wide range of ground conditions and made it possible to excavate even shallowly covered tunnel.

TBM (Shield tunneling)

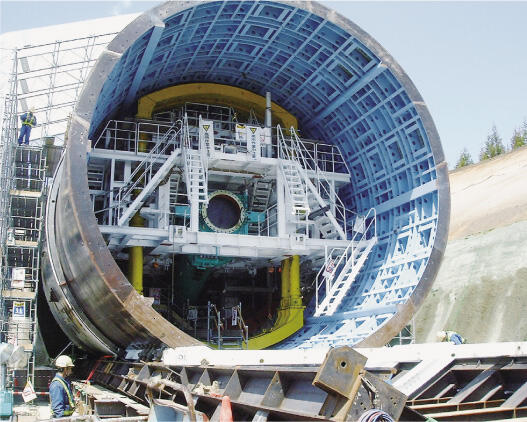

TBM (Tunnel Boring Machine) consists of the cutterhead to excavate the ground and following 'shield part' which supports surrounding soil. Concrete segments are assembled in the shield as a permanent lining thus tunnel can be constructed safely.

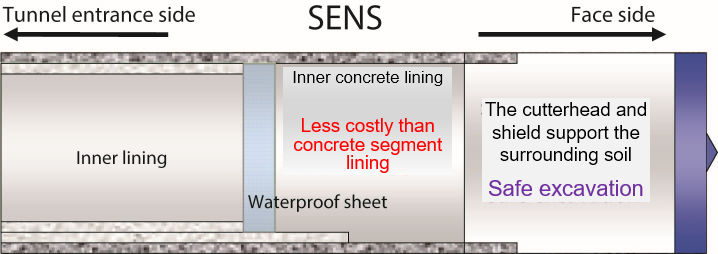

SENS

As mentioned above, TBM is advantageous in safety thanks to the robust steel tube and cutterhead which support surrounding ground, but costly due to the concrete segments for lining which are manufactured in factory.

On the other hand, NATM is less costly but unsafe because workers are exposed to the breakable fresh soil surface during the boring.

JRTT developed a new TBM boring system in which tunnel is lined by less costly site-cast concrete. Combined with auxiliary soil supporters of NATM, it enables safer and less costly tunneling. This system was named SENS, abbreviation from Shield, ECL (site-cast lining), and NATM System, which means it contains various advantages of each boring system.

Primary lining concrete casted in site